SVC Podcast – Show Notes – Show 143-1:

In this edition of the SVC Podcast, SVC Contributing Editor Bennett Liles talks with Laboratory Coordinator John Wilson and Instructional Technology Systems Engineer E.J. Hudock of Lafayette College in Easton, Pennsylvania about their new collaborative geology laboratory where an Extron matrix switcher puts microscope video and many other sources onto a variety of flat screen monitors. They detail the challenges of making a high tech classroom out of a gutted basement that was built in 1899.

Links of interest:

- Lafayette College in Easton, Pennsylvania

- Vistacom’s write-up on the project

- Extron TouchLink Pro touch panels

Download Podcast Here:

https://s3.amazonaws.com/nb-svc/public/public/Vistacom_Lafayette_College…

From Sound & Video Contractor Magazine, this is the SVC Podcast with John Wilson and E.J. Hudock. Show notes for the podcast are available on the web site of Sound & Video Contractor Magazine at svconline.com.

At Lafayette College they totally re-did their geology classroom to have microscope video and other sources matrix-switched to flat screen monitors all over the room. Then they made it a completely BYOD friendly environment. Laboratory Coordinator John Wilson and Instructional Technology Systems Engineer E.J. Hudock are going to give us all the details on it, coming right up on the SVC Podcast.

John and E.J., thanks for being with us on the SVC Podcast from Lafayette College in Easton, Pennsylvania. We’re going to look at the tremendous technology upgrade that you put in place for your geology laboratory. I know that can be a tedious place if you’re staring into microscopes all day but you came up with a great solution for that. John, let me talk to you first. What was the original idea for the lab and how did that evolve as things went on?

John: The original idea for the lab really started as a standard request to the college for a smart classroom. The room was last updated sometime in the 70’s. Dark; it was a basement lab. Kind of dingy; tables were a little old and worn down. And there was no technology in there whatsoever; no computer, no projector, nothing. So everything was kind of done the old-fashioned way and our teaching in the geology department has evolved through the years such that that room did not meet our needs in any way, shape or form. We wanted to make the lab more technologically advanced. [Timestamp: 1:54]

And E.J. when this all went in, since you didn’t have anything in there you had nothing to take out. You pretty much had a clean slate I guess.

E.J.: Well yeah, in the sense that we did end up gutting the room and starting from a blank canvas, if you will. But the design for the room was really a different approach than we would typically do for a standard smart classroom. We were lucky that we have the partnership with Vistacom, who has been our integrator for more than a decade now. And so we’re able to collaborate with them on the design side. So we’re fortunate in that we have a partner in Vistacom that we’ve worked with for more than a decade, so they assisted us on the design aspect as well and we also had another partner in a local cabinet shop, Jonathan Fallos Cabinetmakers, who are located here in Easton. And with everybody in the room, we sat down in this really evolved from sort of a standard classroom idea into a really unique laboratory that it ended up being. [Timestamp: 2:59]

Okay, I’ve seen the pictures of this. How many monitors are there? It looks like you have some pretty big monitors in there.

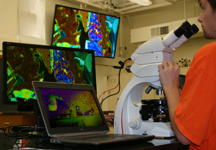

E.J.: The room is laid out with this large table that’s a sort of three-sided rectangle and in the center there’s an island where the instructor has a space. And so at the front of the room there are two 80-inch NEC LED’s that are mounted from the ceiling, and then around the room there’s also 18 stations for students. Each student station has a microscope and a 20-inch NEC computer monitor that’s connected to that microscope. [Timestamp: 3:33]

Well, that’s fantastic because I know it can be fatiguing to peer into a microscope all day. It’s got to be a lot more comfortable to sit back and watch it on a big monitor.

John: It’s a lot more comfortable, but also it’s a lot more academically engaging. I can walk around the room and see my students and see what they’re looking at on the monitor and interact with them instead of asking them to slide over while I look down the microscope and then push back when it’s their turn again. [Timestamp: 4:03]

All right. That’s got to save not only a lot of refocusing and trouble for the students but it’s really got to save you a lot of time in the long run.

John: Absolutely.

And what different sources can you display? It’s not just the microscopes. Can you put other things on the monitors?

E.J.: Yeah. Actually the system is built around Extron XTP Matrix switchers, so everything is really running as an HDMI source; the microscopes and any other device. So we do have the connectivity on the table. [Timestamp: 4:31]

This is an all-Extron system. How do you actually interface the optics on the microscopes? Do you have something that fits over the eyepiece or is it all electronic inside?

John: Each microscope has a module in between the eye piece and the body, which is a camera.

E.J.: So because the whole system is interfaced with HDMI connectors on the inside of the table, the students can just as easily plug a laptop into the system. We also have a document camera available in the room, a Blu-ray DVD player. So essentially any HDMI source can be routed through the system on any or all of the monitors. [Timestamp: 5:06]

And how many ins and outs does it have? How big a matrix is it?

E.J.: We’re currently using 22 inputs and 21 outputs on the system.

Okay, so you can feed all the monitors, you can feed anything to one monitor. Complete versatility.

John: Complete versatility. We can do one-to-one, one-to-many. I can put any scope on any monitors so students can see anything that works for the class. [Timestamp: 5:33]

Where do you have all of this stored? I’m sure it’s not all just sitting out where anybody can mess around with it. Where is the matrix switcher and its associated equipment mounted?

John: The cabinetmaker that worked with us did a great job in designing the table such that all the electronics, as well as the microscopes and monitors, can be easily stored inside cabinets which are built into the table.

Ah, right. So local cabinetmaker and you were able to work with them pretty much on a custom job.

John: Very custom job. He responded to IT’s thoughts and ideas very rapidly to make a system that worked seamlessly with Vistacom’s setup and our needs. [Timestamp: 6:12]

And you’re using all HDMI? Is that the way the video signals are conveyed to the displays?

E.J.: So the displays on the table, everything within the table is essentially just straight HDMI cables. But to get to the instructor’s island in the center, and to the two large displays, we’re actually converting the HDMI using the Covid fiber cable. So we’re actually running fiber optic cables to those locations. [Timestamp: 6:37]

Well, that is special. I don’t think I’ve heard of a lot of places running fiber optic just inside the room but if you have that many displays and that high def a signal, that makes sense.

E.J.: It was more a question of the construction of the room. We had to jump through some hoops to get that cable to those displays that are up on the ceiling. [Timestamp: 6:55]

And how long did you have to do all this; to transform that whole room from start to finish? I think you said in the beginning that you just gutted the whole room and started over.

John: We did. We gutted the room and started over. The whole process took oh, about eight to nine months, but much of it was planning. We started around January-February with planning and acquired funding around late February, at which point in time we were able to iron out the details and get Vistacom set up with what they needed. The cabinetmaker and Vistacom worked through summer to make everything possible and installation occurred the week before the school semester started. And it was a very quick timeline to get it set up. Every day was scheduled from 7:00 a.m. until 6:00 p.m. to make sure every piece of the puzzle got put in in time. [Timestamp: 7:44]

All of that is going to have to work for all of the classes and I know that once classes get in there and it gets to be a busy room, you really don’t have a lot of opportunities for down time or maintenance and upkeep on it.

John: That’s very true. And in order to help facilitate that, Vistacom was very proactive in creating an entire mock-up of our room in their facility where they were able to have a complete setup of the system and test it and verify its work before they ever brought it to the building. When they came and installed it, everything was already proven and working so all they had to do was hook up the wires, run the various cables and press go. [Timestamp: 8:28]

All right. So were there any surprises or anything that didn’t go exactly as planned as far as running cables? Sometimes you run into things behind walls that you didn’t know were there.

E.J.: Well, we were installing this room in the basement of a building that was built in 1899, so no, nothing unexpected there. We had an uneven ceiling to deal with, a concrete floor that had power installed in locations that didn’t work for us. There was some water damage to the exterior walls that had to be remediated. And then the unique piece was there are radiators – heating elements – that run along the wall about seven feet or so up from the floor. So we actually had to tunnel behind them through the brick wall to get those cables up to the displays. [Timestamp: 9:13]

Okay. I know that once this all was in, there was some testing to do and maybe working out a few bugs. How did it go? Did you get some new ideas as you went along or how did it evolve?

E.J.: Well, once we got to the installation point, as John mentioned, because we were able to mock up the system at the Vistacom shop; we went there and sort of did this proof-of-concept. John and I made a couple of changes with the programmer to the touch panel interface at that point, but by the time the gear arrived on campus, it was just a question of installing it in the room and it was up and running in a couple of hours. [Timestamp: 9:46]

So how was it working with Vistacom on this thing?

John: It was incredible. Coming from the geology side, it was great to have a group that was very responsive to our needs as well as open to our new ideas. A room like this really hasn’t been done before, so we were kind of testing the waters and Vistacom did a great job in filling in the IT components that I would not have known existed. [Timestamp: 10:10]

Well, it sounds like not only an interesting situation but for a building that is that old and to update it to something this relatively high tech is a big job. In Part 2, we’ll get into some more details on the monitors and the matrix switcher and the Extron touch panels. It’s been great talking to you, John Wilson and E.J. Hudock from Lafayette College in Easton, Pennsylvania and the new video upgrades to the totally revamped collaborative geology lab there. We’ll see you in Part 2 with more.

John: Okay.

E.J.: Thank you.

Thank you for being here with us for the SVC Podcast with John Wilson and E.J. Hudock. Show notes are available on the website of Sound & Video Contractor Magazine at svconline.com. Be back with us next week for Part 2 when John and E.J. will get into the Extron touch panels, wireless links and making the classroom BYOD friendly. That’s on the next SVC Podcast.