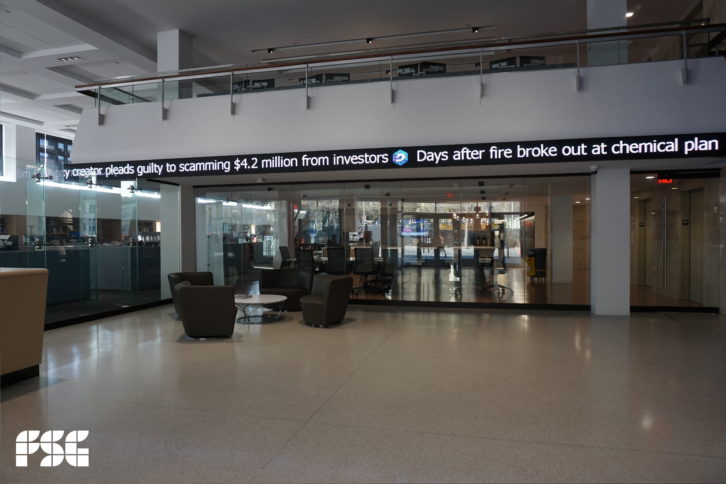

The Dallas Morning News was moving into a historic building downtown and wanted to make a statement with their new headquarters. Designers envisioned a huge news ticker to scroll above the lobby; Facility Solutions Group teamed up with Nanolumens to get the spectacular result. FSG project manager Gerald Reeves is here to tell us about it.

SVC: First let’s hear a bit about Facility Solutions Group.

Gerald Reeves: Thanks again for having me. Facility Solutions Group was started over 30 years ago by a couple of brothers and a friend. They sold lightbulbs for local distribution. It grew into a contracting business for electrical and then they jumped into low voltage about 10-12 years ago. They provide signage, both physical and digital, and a variety of other services. It’s a $600 million company now; it provides both local and national electrical lighting technology and signage solutions to multiple partners—both Fortune 500 companies and mom-and-pop shops around the corner.

This was a local job for you since you’re in the company’s Dallas office.

That’s correct. Our corporate location is based in Austin, but Dallas is our largest market. We also have offices all over the country.

What did the Dallas Morning News specify when they came to you with this idea?

They were looking to have the same feel as a downtown Times Square news organization. And they wanted to develop a classic downtown newspaper motif but use the latest technology to do so. The content that rolls across the display actually comes from folks in the organization—they’re live messages. So it’s very much in the moment.

It’s mounted overlooking the lobby so it would definitely be the first thing you notice when you walk in.

Correct. The building itself is the old Dallas Library. It was built in 1954. There’s a mezzanine around the structure in the lobby and around the side. The fascia of that mezzanine is where we mounted the digital signage display – the ticker, so to speak. So one of our challenges was to get approval from the historical society. We had to jump through some special hoops to make this all work.

I’ll bet you did, and that must have complicated things.

Yes, it did. But one of the things that we pride ourselves in is we’re not just a construction company. We have people from all walks of life working here that have all kinds of experience. Combined, it’s thousands of years of experience in different aspects and markets. We capitalize on what we do know and try to learn from what we don’t. In this case, we went in not knowing what we were going to be dealing with, at least on the front side of it.

Did you have to make any sort of architectural modifications to allow the old structure to support this new display? What about the historical politics involved?

Did you have to make any sort of architectural modifications to allow the old structure to support this new display? What about the historical politics involved?

Yeah, we were hindered by the historical society from actually mounting to the fascia from both a structural and historical perspective. We were able to get them to approve making penetrations in the plaster on the front of the fascia and basically floating our ticker on the fascia. It doesn’t actually touch the fascia anywhere structurally. It protrudes through it, through mounting brackets that we designed and that mount to the underside of the mezzanine in the concrete. So we had to come up with a pretty detailed plan and engineered solution.

I believe you did some 3D modeling?

Yeah. We worked with folks from the contractors there onsite as well as Nanolumens and our team. We designed a mounting system we thought would work and we went back and forth a few times with the folks at Nanolumens to ensure that we were actually okay with their structure. We created 3D modeling with the existing space along with the Nanolumens dimensions, and we built a full 3D mockup to make sure it was going to work. Then we also obtained a structural signoff to make sure we wouldn’t have an issue with too much weight.

What is the weight?

You know typically digital signage, depending on what solution you’re working with, is a relatively heavy product. This was only 550 pounds all-in with mounts and power supply, so considering it’s 75-foot long it seems like it probably would be heavier. However, the Nanolumens product is not all that cumbersome, so it was easy to work with. And that 500 pounds was distributed across 75 feet.

You’ve got a continuous display that has to be readable from close up and far away in addition to a very wide field of view. What are the actual specs?

It’s a 6mm pixel pitch. We chose that size for various reasons. The unit itself is 75 feet long. It’s essentially 30 feet on the front and 45 along the side, which is where most of the newsroom folks are sitting. The ticker itself is two panels tall, so 12 inches.

The newsroom appears to have a lot of windows and interior glass walls. Did the ambient light levels present you with any problems on this?

You know it didn’t present as many problems as we’d expected. I think what was more important to everyone involved was that the image was visible from the outside. We typically think of ambient light is an interior issue. But when you’re trying to project your image to the outside of the building, you have a lot of factors. There’s glare on the outside of the glass to the wall, there are reflections from the street, from the sidewalks, from other buildings. We were fortunate the product that Nanolumens provided could achieve what we really wanted and make the images visible on the outside of the building.

What about the content, who controls it and how?

In this case, we had a server that came with the unit. It has a specific software on that is separate from Nanolumens. The Dallas Morning News team actually provide staff to maintain the software as well as provide the content that goes on that software. We were fortunate enough to be able to provide them with a service-level agreement from both the software and the hardware providers to give them a little added level of comfort in terms of what they purchased.

How did you manage to keep the workflow going without your crew and the news staff getting in each other’s way?

Well luckily this was installed prior to them taking possession of the building. I think our biggest hurdle was working with other contractors and construction teams onsite, dodging the scheduling and that of all the other trades. But really what helped, I think, was really good communication on the front end. We also had consultant-assisted buy-in from everyone involved. That was a really big asset for us.

FSG does a lot of this type of work, so can you give us the basic guidelines you follow on digital signage?

I can think of three things that really stand out for us, and this really isn’t just for digital signage. First, plan ahead. You can really never start too early. A lot of times folks think that digital signage is really an afterthought, but the moment you know that you’re going down that path, start the coordination process. Then, number two, I’d say add 20 percent, whether that be time and/ or money. We all know construction rarely stays on schedule—whether that’s groundup or tenant-finished construction. Just when you think you’ve got it all figured out, the schedule slips and now this month turns into next month. There is a lot of coordination that must happen in digital signage. And then I would say, third reveal the process. I think it’s really critical that everybody involved buys into the expectations of what goes on with digital signage. A lot of times, as contractors and integrators, we try to hold things tight to the vest. But general contractors tend to want to partner with you more when you can reveal the process to them and let them in on what you do a little bit. You don’t have to give all your secrets away but it really is helpful to get their buy-in early on when you can make sure that all expectations are communicated and agreed to. In this case, one of the biggest hurdles was getting signoff not only from the owner but from the construction team, the consultants, the architects, the historical society—there were a lot of people involved.

How long did it take you to get the whole thing in and tested and ready to go?

You know amazingly it took us about a week and that’s it. It was a very quick turnaround. Again, we go back to what we said earlier. If you plan ahead you minimize and can take care of a lot of mistakes or issues on the front end or at least head them off at the pass.

What about maintenance?

Nanolumens provides a certain percentage of extra panels that are color-matched to the ones we purchased. So should a panel go out, we can easily swap in those spares and they’re essentially plug-and-lay. That’s a really nice feature. The can itself— the back can of the ticker—is a powder-coating aluminum housing and they come in five-foot sections. So if there ever needed to be any work done they come apart very easily. I think the biggest hurdle for maintenance is going to be that mezzanine wall fascia. If we have to take apart one section of the display we would need to support it in that spot where it’s disconnected so it would not put undue weight on the mounting points.

So, looking ahead, what’s in the pipeline for FSR?

We have another outdoor entertainment venue scheduled. And then we’ve got several indoor gaming centers coming across Texas that include video walls. We’ve also picked up a couple of customers that want us to service their video walls and digital signage solutions from past installations. So we’re not only selling signage but we’re servicing it, even those that we didn’t install.

To listen to the PODCAST