It’s a graphene-based aerogel and it’s reportedly the lightest sound insulation material ever manufactured, say researchers at the University of Bath. As detailed in their paper at Nature Scientific Reports they demonstrated its ability to damp down noise by up to 16 decibels despite weighing just 2.1 kg per cubic meter (0.13 lb per cubic foot).

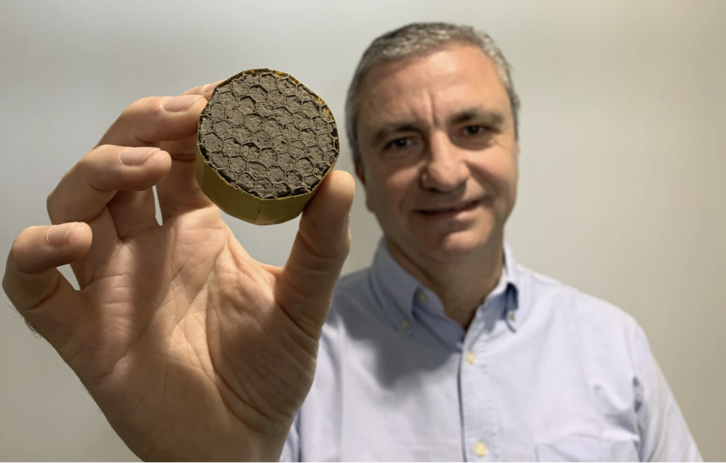

For context, a comparpable conventional polyester urethane sound absorber can carry a density of 32 kg/m3 (2 lb/ft3). So in a given application, this new “graphene oxide-polyvinyl alcohol aerogel,” squeezed into a Nomex honeycomb, would weigh less than one-fifteenth of an equivalent traditional acoustic foam installation.

Researchers put this into a real life context Nowhere that if applied to a jet engine it could potentially reduce the cabin noise of an airliner from the current 105-dB roar to something closer to a 95-dB hairdryer.

“This is clearly a very exciting material that could be applied in a number of ways – initially in aerospace but potentially in many other fields such as automotive and marine transport, as well as in building and construction,” says Professor Michele Meo, who led the research. “We managed to produce such an extremely low density by using a liquid combination of graphene oxide and a polymer, which are formed with whipped air bubbles and freeze-casted. On a very basic level, the technique can be compared with whipping egg whites to create meringues – it’s solid but contains a lot of air, so there is no weight or efficiency penalty to achieve big improvements in comfort and noise.”