Hitting The Mark

Ironically, as cathode-ray tube (CRT) imaging continues its slow march into oblivion, it’s still the most accurate way to reproduce color of any electronic imaging technology.

Pete Putman, CTS, ISF

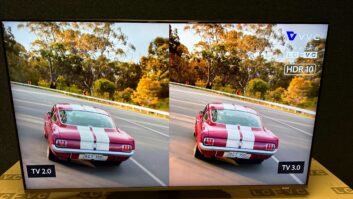

FUNNY THING about color: No two people see it the same. And no two displays render it the same way — without a little bit of help at least. Ironically, as cathode-ray tube (CRT) imaging continues its slow march into oblivion, it’s still the most accurate way to reproduce color of any electronic imaging technology.

That’s because CRTs are intrinsically neutral when it comes to creating grayscale images. By using an accurate color temperature meter or radiometer and adjusting both the gain and bias for each color gun, we can literally “paint” whatever palette we want, subject to the limitations of the rare earth phosphors.

Things are completely different with fixed-pixel displays. These use everything from cold-cathode (fluorescent) and short-arc mercury vapor lamps to xenon arc lamps as light sources, shuttering or reflecting the light as needed through individual red, green, and blue color filters or multi-segment color wheels. (Plasma panels are different because they also use stimulated phosphors.)

The problem is, none of these illuminants have equal spectral energy. Cold-cathode lamps tend to have too much greenish-blue energy, and not enough warm reds and yellows. It’s the same with mercury vapor lamps, such as the popular UHP and UHE series. Only xenon arc lamps come close to the ideal illuminant, which is the sun.

That means the color of white produced by any of these displays can vary considerably across many thousands of degrees Kelvin (K). Indeed, “white” can be anything from 5,000 degrees K (slightly warmer than natural daylight) to 6,500 degrees K (the NTSC standard) and even higher (9,300 degrees K, a common setting for computer monitors).

For fun, throw in some additional variables, such as the weighted NTSC and HDTV color systems (59 percent green, 30 percent red, and 11 percent blue, corresponding to human color sensitivity) and the cultural bias that finds some people favoring warmer electronic images (North America) and others favoring cooler electronic images (Asia).

Nevertheless, an electronic display must be calibrated to some standard if its color space is to match the palette used by the creator of the content being shown. This isn’t as big an issue with simple business graphics, but it is of major concern when viewing video and films transferred to video.

Some manufacturers of projectors and flat-panel displays are already incorporating adjustments for red, green, and blue contrast and brightness to enable this sort of fine-tuning. For imaging technologies using pulse-width modulation, such as digital light processing and plasma, only contrast or drive controls have any real effect.

To take advantage of them, you’ll need a color meter that can reference the light source in use and the starting values of red, green, and blue. Otherwise, your calibration efforts may go to waste as the readings you obtain don’t agree with what you see happening on the screen.

Here’s an example: Many front LCD projectors that have RGB adjustments will actually produce images with a magenta tint when most color temperature meters are reading “D6500.” That’s because the meter reading is being taken to the closest part of the “black body curve,” rather than right smack on it. Taking a reading with “x” and “y” coordinates instead of the absolute color temperature will usually reveal how far off the measurement is from a neutral white.

I recently had a chance to test Minolta’s new CS200 radiometer, an $11,000 light meter that can perform a range of color temperature readings. Just to see how readings vary from one meter to another, I set up several different test displays including a Dell 19-inch LCD monitor, a Canon 1400×1050 LCoS front projector, and my reference Princeton AF3.0HD 30-inch HD monitor.

For extra fun, I compared readings from the CS200 to my handheld Minolta CL200 light and color meter and an older Progressive Labs CA-1 color analyzer. Needless to say, the three instruments rarely agreed with each other — and sometimes the most accurate reference was a simple gray card and my eyes.

As a test pattern source, I set up my AccuPel HDG2000 generator to output 720p grayscales, gray fields, and red, green, and blue fields to establish color coordinates. In component YPbPr output mode, the color matrix should be weighted to 59 percent green, 30 percent red, and 11 percent blue.

For my tests with the CS200 and the Princeton monitor, those weights were 62.7 percent, 29.4 percent, and 7.9 percent, while readings with the CL200 handheld meter resulted in weights of 71 percent, 22.7 percent, and 6.3 percent. Right off the bat, I had either a problem in the generator (not likely, as it was recently recalibrated) or an error in the green and blue sensors — more pronounced in the $3,000 CL200 than in the $11,000 CS200.

Things got even more interesting when I calibrated the Princeton for a neutral grayscale image using my CA-1 analyzer to get 50 percent gray as close to D6500 (.313x, .329y) as possible. The CL200 meter showed coordinates of .3129x and .3303y with a color temperature reading of 6,495 K, but the CS200 readouts showed .3277x and .2177y for 5,745 K — a difference of 750 degrees.

Obviously, one of the meters was not reading the values of RGB correctly. The reference grayscale looked to be very close to the ideal D6500 value, and at least two of the light meters agreed with it. Perhaps the CS200 required “learning” the phosphor color values?

Things got more interesting with the Canon SX50. This projector uses a short-arc ultra high-pressure lamp, and its spectral output is quite uneven. Nevertheless, I performed a grayscale calibration using the CL200’s “multi” operating mode, which is usually pretty accurate with this type of lamp.

Comparing the readings from the CL200 and CS200, I saw a difference in measurements of about 300 to 500 degrees at three of the four steps, with the CL200 reading the 25 IRE gray pattern about 1,600 degrees higher than the CS200. In this case, I’d have to defer to the more expensive instrument, as my own eyes told me the color shift wasn’t that pronounced.

My final test was to measure the Dell W1900 LCD monitor with the CA-1 and CS200 analyzers. I selected an 11-step grayscale ramp from the HDG2000 and once again tried to calibrate to a neutral gray, using my Princeton monitor as a reference.

While the readings varied by as much as 1,300 degrees between the two meters at the low end of the grayscale, they were considerably closer from 50 to 100 IRE. This would seem to indicate a problem with low light sensitivity in one of the two meters. Given the age and history of my CA-1 (it specifically needs to learn RGB values for non-CRT displays), I would suspect it to be the more inaccurate model.

What’s the point of all this? If you’re installing monitors into a facility where color accuracy is a concern, you’ll need to not only invest in a good color analyzer, but also learn how different light sources can affect the accuracy of the readings you take.

Minolta’s CS200 can learn any color matrix and you can vary its viewing angle, which is something you can’t do with the lower-priced CL200. The companion CS-S10W software lets you automatically or manually log readings at various time intervals, and the data is saved in a useful table format for analysis. It can also be exported to text files and ultimately to a spreadsheet.

However, the CS200 is a bit bulky to move around, and you’ll need a tripod to support it. The CL200, on the other hand, is far more useful for calibrating front projectors as it has that second “multi” operating mode, which can be set up to read short-arc lamps more accurately. You can also export the data from this meter to a PC for capture, logging, and editing.

While a useful gadget in its day, Progressive’s CA-1 analyzer has been replaced with a new model that no longer requires learning of red, green, and blue values from different kinds of lamps. It’s now part of a package from Ovation Multimedia, manufacturer of the Avia test pattern DVD, and goes by the name OpticONE. All you need to make it work is a Pentium PC running at least Windows 98, and you can also log and analyze color data.

There are other color analyzers available. Sencore currently offers four different models that work with laptops and PDAs and provide color coordinates as well as absolute color temperature readings. And Milori (now part of Datacolor) offers the ColorFacts Professional color analyzer and software suite. If accurate color matching is part of your next job, you’d be well advised to check out any and all of these products.

Pete Putman is a contributing editor for Pro AV and president of ROAM Consulting, Doylestown, PA. Especially well known for the product testing/development services he provides manufacturers of projectors, monitors, integrated TVs, and display interfaces, he has also authored hundreds of technical articles, reviews, and columns for industry trade and consumer magazines over the last two decades. You can reach him at [email protected].