Soft robots and flexible electronics are more likely to get ripped or punctured. A new stretchable, self-healing conductive material was designed to make them more durable.

The substance was created by a team at Virginia Polytechnic Institute and State University (Virginia Tech), led by Asst. Prof. Michael Bartlett. It consists of a rubbery SIS (styrene-isoprene-styrene) copolymer, inside of which are suspended tiny droplets of liquid metal.

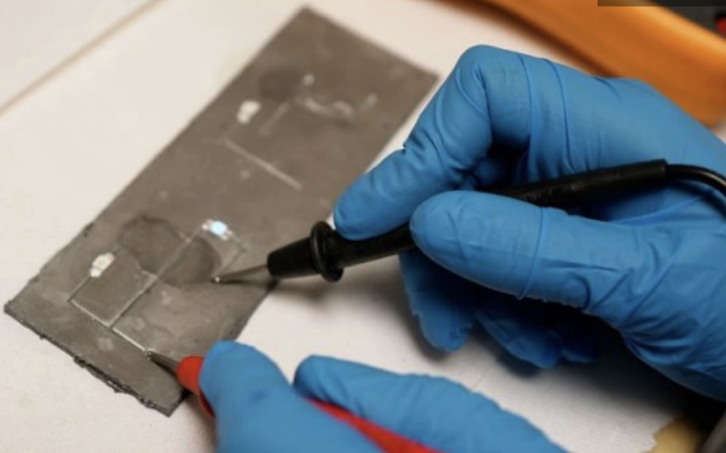

As explained in New Atlas, these droplets are ordinarily separated from one another, so an applied electric current can’t flow between them. When a straight edge such as that of a ruler is pressed into the material, however, it ruptures the barriers between all of the droplets along that line. In this way, people can emboss circuits into the substance, along which currents will flow. Adding an extra layer of copolymer on top of these circuits helps to protect them.

Researchers claim that in lab tests, the material could be stretched by up to 10 times its relaxed state, without losing conductivity. Additionally, if a hole is punched in one of the circuits, the electric current simply flows through the now-released liquid metal around the edges of that hole – thus keeping the electricity flowing.

Importantly, once a device incorporating the technology has reached the end of its usefulness, the material can be recycled and re-embossed with new circuits.

“We’re excited about our progress and envision these materials as key components for emerging soft technologies,” says Bartlett. “This work gets closer to creating soft circuitry that could survive in a variety of real-world applications.”

The research is described in a paper that was recently published in the journal Communications Materials.