Power Sequencing

Power sequencing is needed when various types of electronic equipment must be powered up or down in groups, rather than all simultaneously. In AV systems, sequenced powering is often necessary to allow turn-on transients from low-level amplifiers and processors to settle down before any power amps are turned on, because simultaneous powering would result in a loud, annoying, and potentially destructive pop reaching the speakers.

CHOOSING A POWER SEQUENCER

POWER SEQUENCING IS NEEDED WHEN various types of electronic equipment must be powered up or down in groups, rather than all simultaneously. In AV systems, sequenced powering is often necessary to allow turn-on transients from low-level amplifiers and processors to settle down before any power amps are turned on, because simultaneous powering would result in a loud, annoying, and potentially destructive pop reaching the speakers.

And in any large system whose components present an inductive load to the AC line (including electric motors, power supplies, and power amplifiers of all kinds), sequenced powering can avoid excessive inrush currents that cause circuit breakers to trip even though the steady-state currents are not excessive.

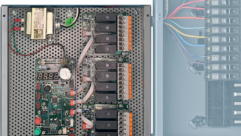

Any power sequencer for pro AV applications should be rack mountable, manufactured in a heavy duty steel chassis, be rated for at least 15 amps, and offer basic spike/surge suppression and RFI filtering. Other considerations include:

- Number of outlets and delay groups: Two delay groups may be adequate, but sometimes three are needed. Six outlets is minimum (two for each delay group), and eight is preferred, with two or more unswitched. An unswitched outlet on the front panel is always handy.

- Adjustable delay intervals: The capability to adjust the delay (internally or externally) allows maximum flexibility.

- Daisy-chain capability: If one unit doesn’t have enough outlets or power capacity, this lets you daisy-chain sequence control to multiple units.

- Status and line fault indicator: Better sequencers for professional use will have indicators to show which delay groups are on, and perhaps other features such as line fault indicators to help analyze any faults in the AC mains wiring.

- Special circumstances: Larger and more sophisticated installations may require 20A capacity or more, remote switching, a locking key power switch, more sequence groups, and more flexibility in controlling additional 15-20A circuits.

All these features are available in various models of professional power sequencers. Variations in type of control signals needed (maintained, momentary, normally open, normally closed) is highly desirable. For large installations, one or more sequenced power distros that utilize 120-amp service and distribute it to six 20-amp circuits that can be powered up and powered down in a user-adjustable sequence may be appropriate. Sequencing-only units that provide power sequencing signals for multiple devices are also available. Some of the devices that can be powered by a “sequencing only” device would include 15A and 20A quad box mount, as well as surface mount power relays.

SOURCE: FURMAN SOUND