Without electricity there’s no AV. And anyone who’s been doing this for a while has seen the steady increase of power cords and power supplies in racks, consoles, credenzas, above the ceiling and under the floor. What seems like a simple and obvious aspect of AV systems has a variety of complications and special conditions.

In the U.S. and a few other countries, power is usually delivered to the wall outlet (what electricians call a receptacle) as nominally 120 volts AC (alternating current) at 60 Hertz (cycles per second). Branch circuits in commercial buildings are typically rated at 20 amperes of available current, while residential may be rated at 15A. In neither case can equipment actually draw the full current continuously, as protective circuit breakers generally hold sustained loads to about 80% of maximum. The design intent of electrical systems necessarily puts safety first. Despite what may seem like onerous and complicated rules, the National Electrical Code is entirely about safety and is updated regularly to account for new conditions (sometimes even the special needs of AV systems).

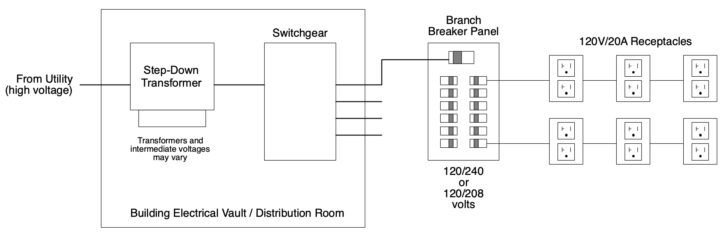

The opening image at top is simplified building power distribution. Each circuit is fed from a circuit breaker in a breaker panel (panelboard) and usually feeds several receptacles in parallel. Power is typically delivered to a panelboard, or a whole building, as something higher than 120V, in various configurations that use transformers to distribute loads across different generated phases. Further details are beyond the scope of this article, just be aware that voltages well above 120V may be present!

Power in Europe and most other countries is based on 240V nominal, at 50Hz. Before switch-mode power supplies became common, using equipment between countries involved a transformer to convert the voltage, as well as adapters for different wall outlet configurations.

SOURCING DC POWER

Internally all of our equipment, as well as LED lights and consumer electronics, uses DC (direct current). A power supply, sometimes called a converter (or a driver for LEDs), is required to convert the 120VAC to one or more DC voltages, typically between 5V and 24V. Within equipment the DC voltage may be further converted as required. Occasionally equipment will take a low AC voltage as the input and convert to DC internally.

Audio and video equipment from before about 1990 likely has an AC power cord directly attached (or with the familiar IEC-C14 socket) and an internal power supply. These were often linear supplies, where the conversion of AC to DC is done with simple step-down transformers and diodes, followed by DC voltage regulation. They tend to be robust and tolerant of power line problems. Figure 2 shows two 9V supplies in the familiar “wall-wart” package we all know and love. Look carefully at the specs, one is 9VAC.

Much of today’s equipment uses switch-mode (switching) power supplies, which can provide a lot of power in a small size and may accept a wide range of AC input voltages (handy for international use). Some equipment has the switch-mode supply inside, but Figure 3 shows two common 5VDC wall-warts. The one on the right is an old linear supply; notice it’s larger but has less current capacity than the switch-mode version. Also note the different polarities indicated for the plugs; center-pin negative is a bit unusual.

Unfortunately, once manufacturers started using cheap commodity switch-mode supplies, instead of designing their own or buying high-quality ones (linear or switch-mode), we began to see a decline in reliability. In my experience, it’s more likely that the power supply will fail than the equipment, and I always check those first.

Note that most single-voltage wall-wart power supplies are not unique or proprietary to a specific piece of equipment. The manufacturer’s (often expensive) supply may be higher quality, or it may not. But in a pinch, you can usually substitute any supply of equivalent voltage, current capacity, and plug type (including polarity).

It’s also possible to purchase high-quality external supplies that should outlast the ubiquitous cheap ones. For that matter, if your installation suffers from wall-wart chaos, some manufacturers sell power supplies that can replace multiple wallwarts for their equipment. Generic versions are also available that will provide different voltage outputs on numerous individual connectors.

In addition to powering equipment with internal or external power supplies, there are various approaches to sending power along with signals. Some are proprietary to a manufacturer or product, while some, like Power Over Ethernet, are standardized. POE usage is growing in AV because there are more and more devices that use the network as their primary signal connection. POE puts between 45 and 60VDC on the same wires as ethernet data, using a scheme similar to microphone phantom power. There are several IEEE standards for POE that support different wattage levels (pay attention to these specs). When a cable is connected to POE ports on a network switch or POE injector there is a “handshake” process to check if the connected device should receive power, and how much is needed. Using large numbers of POE devices, long cable runs, or large cable bundles may require attention to parameters like maximum available power and cable spacing (to allow heat dissipation).

In large data centers there is a trend for equipment that can run on external DC power from a central source. Distributing DC power can make a lot of sense, especially for large installations. Why send AC to every device just so it can be converted to DC? DC distribution is also available for architectural products like LED lighting. This approach can be cost-effective, and also better for the environment, but is not yet common in the AV world.

USING VOLTAGE AND CURRENT

An important point to remember about specifying power in both AC and DC configurations is that the supply voltage must match the device, but the supply current rating can be higher than what is required. This is because current is only drawn as-needed from what is available. For example, if you want to replace an original DC supply that’s rated at 5V/2A, it’s fine to use one that’s rated for higher current, as long as it’s still 5VDC. Anything over 2A is simply available capacity that’s not used. Arguably, it’s not wise to replace a 2A power supply with something really large, like 10 or 20A. Those would still work but could cause serious damage in the event of a malfunction down the line.

Specs written on the equipment, or in the manual, are a good guide for replacing a power supply, or for determining how much power a rack full of gear will use. This is important when determining how many AC power circuits are needed, and also how much cooling may be required.

Voltage and current together determine how much energy is used to do work. Real power, expressed in watts, is often calculated as voltage x current. When figuring how much power might be used in a configuration, adding up the stated wattages (or VxA) of all the equipment will provide a good high-end estimate, since gear generally doesn’t use the maximum power all the time. For example, with audio amplifiers the continuous power might be much less than what the amp draws on loud peaks. Likewise, a computer power supply may have a maximum wattage based on a chassis fully loaded with CPUs and drives.

Devices with motors, tons of fans, or lots of spinning hard drives may use little power most of the time but have a high startup current. The power supply must be able to handle that brief high demand, so the maximum current spec should be taken into account even though the typical load is modest.

When asked by the HVAC engineer how much heat the equipment will produce, a simple rule of thumb is to assume that all the wattage used will be converted to heat. This is an overstatement, but it’s close to reality for a lot of gear and provides some leeway. The total wattage is converted to BTUs (British Thermal Units) in order to calculate the cooling load.

BACKUP POWER

Large, mission-critical facilities, like TV stations or emergency control centers, generally have gas-powered generators that switch in automatically if grid power fails. Some facilities may have flywheel generators or rooms full of batteries for short-term support. For smaller projects an uninterruptible power supply (UPS) is the way to provide backup power, and some amount of protection. Commercial models are available for 3-phase AC and very large capacities, but it’s common in AV systems to use a number of rackmount or tower UPSes. These are mainly intended to keep things running long enough to shut down computers and drives or finish a process like transferring files.

Home and commercial UPSes have historically used lead-acid batteries–same as in cars–but models using lithium-ion are also available (follow instructions for safe handling). UPS batteries usually need to be replaced every 3-5 years, and every UPS has some kind of warning for battery failure. Fancier models also have menus to access many electrical and operational parameters, as well as the ability to connect with computers for control or automatic shutdown. In fact, UPSes have become so sophisticated that setting them up can be a chore.

The UPSes found at consumer stores are usually offline (standby) types, which means that the load equipment is connected directly to the power line, and if power fails the UPS switches to battery within a few milliseconds. These are the least expensive and don’t provide much, if any, protection from other power line problems. A second UPS type, line-interactive, adds voltage regulation when the load is connected to the power line, and may have better surge protection.

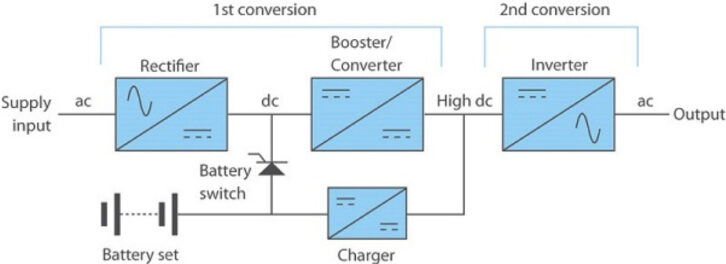

The most sophisticated UPS is the online (double-conversion) type. In this design the incoming AC is converted to DC for the batteries, and that DC is also used to run the inverter, generating fresh AC power at all times. The load is never connected to the power line, which provides the ultimate protection from surges and noise. Online UPSes are the most expensive, though some cheaper models may provide a stepped-sine-wave output. I almost always specify an online UPS for critical equipment (I’m partial to Eaton) and don’t skimp. Good ones should last through many battery replacements, so it’s a onetime investment in the well-being of the facility (Fig 4).

UPSes are usually sized based on their volt-amp (VA) rating, which can be confusing. VA is another measure of power but is not always equivalent to watts. While W tells how much energy is turned into real work (lights, heat, sound, computing), VA expresses apparent power, which includes extra energy that is needed due to inductive loads like motors and transformers. The ratio of watts to VA is a percentage known as power factor. A high-power factor (closer to 1 or 100%) means more of the energy used is doing work.

So a decent sized UPS for a rack of equipment might be rated at 2kVA (2000VA), but only 1400 watts. That 30% difference is an assumption that the load on the UPS will have a power factor of 70%, which was not unusual when equipment power supplies were mostly linear. The change to switchmode power supplies has had the positive effect of reducing inductive loads, which means it’s possible to use UPSes designed for a 90% power factor (such as the Eaton 9 Series) which can support more gear.

In my experience it’s the wattage that matters for operating AV equipment, and a good UPS will indicate when the amount of power being drawn exceeds its capacity. Note that while it’s tempting to buy a bigger UPS instead of several small ones, going above 2kVA means the UPS will require a 30A circuit from the building. As it is, a 2kVA model will come with a NEMA 5-20P plug, with one blade turned 90-degrees, which requires a 20A receptacle.

Lastly, manufacturers provide tables that indicate how long a UPS can support a particular load (run time). Often additional batteries can be added, but since the usual goal is just to shut things down gracefully, long run times may not be worth the extra cost. Why keep an AV system going when the rest of the building is dark?

POWER CONDITIONING

A downside of the move to switch-mode power supplies is an increase in harmonics that distort the sine waveform of the AC line they are plugged into. This harmonic distortion (the same principle as with audio) can cause various problems with equipment that is sensitive to it. This includes inductive devices like motors and linear power supplies, and some other electronic devices.

Unfortunately, it’s easy to say that “harmonic distortion is bad” and not so easy to determine when it actually matters. It’s definitely an issue in industrial settings, with equipment that operates directly on AC power. But in our AV systems, the switch-mode power supplies that cause the harmonic distortion are the same ones using the electricity. Ironically, the input stages of UPSes can also add harmonics to the power line.

Furthermore, while a double-conversion UPS isolates the load equipment from noise on its line side (the building power system), all the equipment on the load side of the UPS is now sharing a “new” common power source which can be contaminated by the equipment itself. Hmmm.

Nevertheless, there are some power line issues that a double-conversion UPS will solve. For starters, under and over-voltage conditions may occur for any number of reasons beyond our control. Arguably, switch-mode supplies that can operate from 80 to 240V might not care, but running at a lower voltage means drawing more current to compensate, so that could have ramifications on circuit capacity, heat generated, or power supply life.

A second issue is instability after a power loss. The power company source may come back unevenly for a few seconds before reaching a stable voltage, and this is a likely cause of power supply failures–particularly the cheap ones.

An online UPS will also do the most to protect against spikes and surges (though might not survive a lightning strike itself). Other types of surge protection include everything from cheap power strips with metal oxide varistors (MOVs) to sophisticated series-mode surge suppressors. How useful each might be is a point of contention.

The subject of power conditioning has great potential for misunderstanding, hearsay and marketing nonsense, and there’s a tendency to assume that the “best practice” is to include such things in a system because… Well, at least you can say you did. But if a system works great for years it’s impossible to know whether not using a UPS or a conditioner would have changed anything.

In the end we want to feel good about our projects and provide good results for our clients. I have come to my own resolution about handling power quality, which basically is to use online UPSes for critical areas. I advise being skeptical of claims about “dirty power” and how to fix it. If you want deeper answers, do your own research and return to the science.

In the end we want to feel good about our projects and provide good results for our clients. I have come to my own resolution about handling power quality, which basically is to use online UPSes for critical areas. I advise being skeptical of claims about “dirty power” and how to fix it. If you want deeper answers, do your own research and return to the science.

POWER PHILOSOPHY

The last topic here also brings some controversy, as well as new environmental considerations. Broadcast facilities, data centers, server rooms and many large AV installations are designed to remain on 24/7. Sometimes their function requires it, but in other cases equipment is idle for hours or days. Should it be left on? What about small installations that are only used occasionally?

My experience over three decades has been that lots of equipment is “happier” when left on, rather than being powered on/off for every use. When a stable temperature is maintained, and components are not regularly being thermally cycled or jolted by power starting up, the system just seems more reliable. In addition, software has loaded, internal processes are running, and there’s less chance of a fatal startup error. My evidence is anecdotal, but it seems that I get fewer surprises returning to gear that has been left running, than when turning it on cold. This is how I run my office computer (with an occasional restart to clear memory trash).

Given that assumption, it’s easy to see applying it to “core” equipment like routing and production switchers, processors, conversion, IT and most gear that lives in AV racks. The same for servers and computers. A critical point, of course, is that those environments generally have proper cooling 24/7. If equipment cannot be kept at a moderate temp (say below 72F) it may be better to turn it off.

I generally apply this philosophy to equipment that’s located elsewhere but is part of the same system, such as control panels, KVM devices, and other user-facing gear–again with the caveat that it not be left to overheat! I will also leave computer monitors on, as long as the associated computers go into sleep mode (and the monitors do too).

The main exception, going all the way back to the CRT days, is large displays. For starters, displays probably use the most energy and produce the most heat of any equipment still found outside a server room. Second, some display types, such as OLED, can develop burn-in if a static picture is left up for long periods (this was also true of CRT and plasma). Third, displays use components that age in noticeable ways, which may be accelerated unless they are designed to run continuously.

Having made a case for letting most equipment run, how does that square with the movement toward a more “sustainable” AV industry? On the positive side, the days of big, power-hungry processors are over, and even large servers may include energy-saving options. We’re using less power and making less heat in each installation, though there are more installations than ever. Is it sensible to keep a room full of equipment running, and cool, if it’s not being actively used? At this point I don’t have a position that balances the issues, but it’s a discussion that will need to happen.